Running a transient response analysis

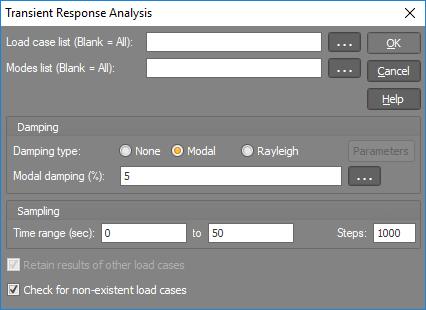

You can run a transient response analysis by selecting "Transient Response Analysis" from the Analysis menu.

![]() Before a transient response analysis can proceed, you must have created some transient load cases and performed a dynamic frequency analysis.

Before a transient response analysis can proceed, you must have created some transient load cases and performed a dynamic frequency analysis.

Load case list

Leave blank if you want to analyse all transient load cases, otherwise enter the load cases (separated by commas or dashes) that you want analysed.

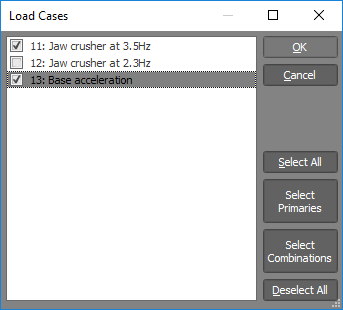

When specifying the load case list, you can either list them directly or you can click the ![]() button to display and select from a list of

the transient load cases currently in the job as shown below.

button to display and select from a list of

the transient load cases currently in the job as shown below.

Mode list

The transient response analysis uses the mode superposition method, and this field allows you to specify which modes from the dynamic frequency analysis are used. You can leave it blank so that all analysed modes are used (the usual case) or you can enter a list of modes separated by commas or dashes. The main reasons for specifying a list are to see the effect of particular modes on the analysis or if you have chosen modal damping with different amounts of damping for each mode, however in most circumstances you should just leave it blank.

Damping

The process by which free vibration steadily diminishes in amplitude is called damping. In actual structures, the damping mechanisms include friction at steel connections, opening and closing of micro-cracks in concrete, fireproofing, and friction between

the structure itself and non-structural elements such as partition walls.

As you can imagine, it is almost impossible to identify and quantify all of the damping mechanisms in an actual structure and so damping is usually represented in a highly idealized manner. One of these is the "damping ratio" which

is the ratio of the actual damping to critical damping, where "critical damping" is the smallest amount of damping for which the structure returns to its equilibrium position without oscillating after the load source has been removed.

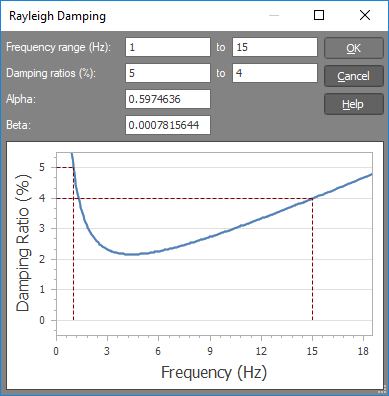

SPACE GASS allows you to disable damping or specify it as "Modal damping" or "Rayleigh damping". Modal damping uses a constant damping ratio for each dynamic mode, whereas Rayleigh damping uses a combination of mass-proportional

and stiffness-proportional damping.

If you disable damping then infinite deflections are theoretically possible if the time-dependent load sources induce oscillations in the structure that have a frequency close to one of the natural frequencies of the structure. To avoid this, SPACE GASS applies a very small damping ratio of 0.00001% when damping is disabled.

If you select modal damping then you can have the same damping ratio for every mode by simply inputting a single damping value in the "Modal damping (%)" field. Alternatively, if you want a different damping ratio for each mode then you should enter a list of damping ratios that correspond with the list of modes in the "Mode list" field. For example, if your "Modes list" field contains "1-5,6-10,11-20" and your "Modal damping (%)" list contains "5,4.5,4" then modes 1 to 5 would have 5% damping, modes 6 to 10 would have 4.5% damping and modes 11-20 would have 4% damping. Or if your "Modal damping (%)" list contains just "5" then all modes would have 5% damping. Common damping ratios for buildings are 5% for steel buildings, 5-6% for concrete buildings, 3% for unreinforced masonry structures, 7% for reinforced masonry construction and 7-10% for timber construction. Some sources recommend that the first mode damping ratio also be used for all higher modes. Damping ratios for non-building structures such as bridges or cranes can be vastly different to those for buildings due to the absence of non-structural elements in those structures. It is your responsibility to carefully choose the correct damping ratios for your situation.

If you select Rayleigh damping then you must click the "Parameters" button to select the damping coefficients as shown below. You can choose damping ratios for each end of a range of frequencies or you can specify the a and b mass and stiffness proportionality constants directly. They are used in the formulation of the damping matrix c as follows:

c = am + b k, where m is the mass matrix and k is the stiffness matrix.

The damping ratio xn for the nth mode is calculated during the analysis according to:

xn = a/(2w n) + bwn/2 , where wn is the circular frequency of the nth mode.

Time range

You should set the time range to no more than the range you are interested in. Setting it too wide means that each step has to cover a bigger time increment and this results in a lower result resolution.

Steps

Each step is a snapshot in time at which the structural response is calculated. You should choose the number of steps based on a good compromise between analysis speed, the amount of data that gets generated, and enough sampling points to get a good representation of the structure's response. 1000 steps is usually a good starting point. If you set it too low then you may miss some of the peaks and troughs in the structure's response if they happen to occur between steps. If you set it too high then the analysis will be slower and the amount of data stored with the job will be larger. The number of steps also has a direct affect on the smoothness of the animation and graphs that you can get after the transient analysis.

Retain results of other load cases

Tick this box if you want to keep the analysis results of previously analysed transient load cases. Otherwise, if they are not being re-analysed in the current session, they will be discarded.

Check for non-existent load cases

If you have defined combination load cases that contain other load cases which don’t yet exist, this option will detect and report them. It is optional because some users prefer to have a standard set of combination load cases that contain primary load cases which are just ignored during the analysis if they don’t exist.

When all of the information has been entered, the transient response analysis module performs its calculations for each load case. If you want to terminate the analysis before it is finished, just press ESC or the right mouse button.

To find out what you can do after the analysis, refer to "After the transient analysis".

For information on the transient response analysis results, refer to "Transient response analysis results".