Generate plate mesh from members

This tool lets you generate complex plate meshed panels after defining their geometry with members. The members essentially act as construction lines that can be deleted after the mesh has been created if they are no longer required.

If you would prefer to create a meshed panel without first having to draw members to define it, you should use the "Draw plate meshed panel" tool instead. It has similar capabilities to this mesh tool, albeit with some advantages and some disadvantages.

You should start by drawing members that define the panel's boundaries, openings, sub-panels and internal walls. Note that openings and sub-panels are detected from members that form closed polygons. The members used to define openings, sub-panels and internal walls are known as "hard lines" because they must be included in the final mesh without being moved or re-sized. Similarly, "hard nodes" are nodes that are to be part of the mesh without being moved. "Sub-panels" are simply panels within a main panel that may have a different thickness, offset or properties to the main panel, such as a drop panel for example.

You should then select the members in the plane of the panels being meshed, right-click and then select "Mesh Tools" => "Generate Plate Mesh from Members" from the popup menu that appears.

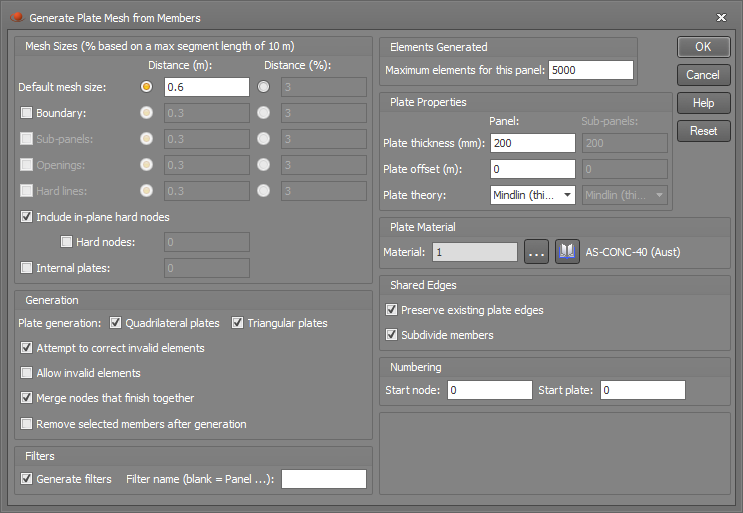

The form that appears next allows you to adjust the various settings that control the meshing.

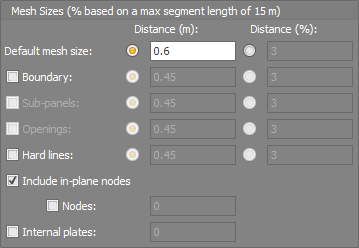

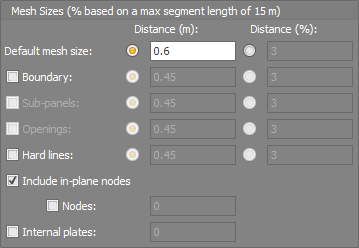

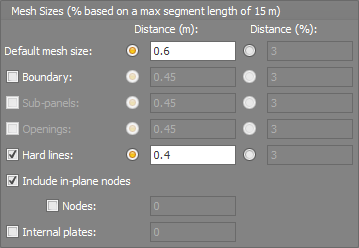

The mesh sizes panel lets you control the size of the elements to be generated in the various parts of the panels being meshed. Each of the mesh size settings can be specified as a length or as a percentage of the maximum segment length. The maximum segment length (15m in this case) is the longest segment in the panel boundary and is determined automatically based on the members you have selected.

The "Default mesh size" is used for any of the settings below it that aren't ticked.

The "Boundary" setting applies to the elements to be generated around the external boundary of each panel being meshed.

The "Sub-panels" and "Openings" settings are not used in this mesh tool, as it treats closed polygons formed by members as sub-panels or openings.

The "Hard lines" setting applies to the elements to be generated around internal members (ie. members that are not part of the external boundary). Note that if you want some internal members to not be treated as hard lines then just don't select them.

If any in-plane nodes (ie. "hard nodes" not connected to the boundary or to hard lines) are to be included in the mesh then you should tick the "Include in-plane nodes" option and optionally tick the "Nodes" box and set the mesh size for the elements to be generated around them.

The "Internal plates" setting applies to the elements to be generated away from the boundary and away from any hard lines or hard nodes.

Note that in order to achieve well conditioned elements while preserving compatibility with the surrounding elements, the requested element sizes may not always be achievable.

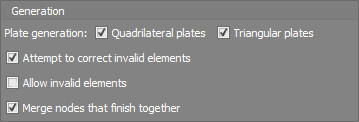

By default, the mesh tool will generate a mixture of quadrilateral and triangular elements, however you can limit it to just one type by unticking either one.

Invalid elements generally occur when an element has an aspect ratio greater than 4:1 or an internal angle greater than 135 degrees. If you tick the "Attempt to correct invalid elements" option then it will re-arrange the mesh and/or split problematic elements into two or three in an attempt to correct them.

Keep in mind that the "Attempt to correct invalid elements" option is not always successful and so occasionally you may get a warning about the mesh not being generated due to invalid elements. In such cases you could either change some of the mesh settings or tick the "Allow invalid elements" option and then once the mesh is generated use the "Find" tool to locate the invalid elements and attempt to correct them manually.

During the meshing process, if two nodes finish up very close to each other and you have ticked the "Merge nodes that finish together" option then the close nodes will be merged into one.

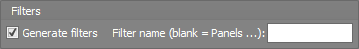

Filters can be automatically generated during the meshing process so that the various components of the finished mesh can be easily isolated and selected. If you leave the "Filter name" field blank then each time you mesh a new panel it will create a filter for that panel called "Panel n", where n is the panel number. If you prefer to define your own filter name then you can enter it into the "Filter name" field.

A filter called "Sub-Panels" will also be created that contains all the sub-panels within the meshed panels. This makes it easy to select them if you want to delete them or change their thickness or offset after they have been created.

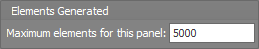

In order to prevent the mesh tool from generating an excessive number of elements, especially if you are unsure of the mesh size settings to use, the "Maximum elements for this panel" setting allows you to set an upper limit that will cause the mesh tool to stop if it is exceeded.

Note that there is still an upper limit of 32765 nodes, members and plates currently in SPACE GASS and so the "Maximum elements for this panel" setting helps you to stay within this limit for your model as a whole. It is planned for this upper limit to be removed in the next major release of SPACE GASS.

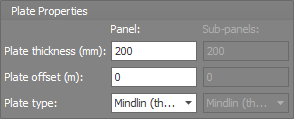

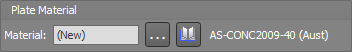

The plate properties and material panels let you set the thickness, offset, type and material of the elements to be generated.

In the shared edges panel you can elect to "Preserve existing plate edges". This applies when a panel being meshed has a common boundary with another panel not being meshed. If you tick this option then the panel being meshed will generate elements along the common edge that match the elements in the other panel so that the two panels are properly connected. If you untick it then the panel being meshed will generate elements independently of the other panel and may result in the two panels not being connected properly. Generally you would untick the "Preserve existing plate edges" option only if the other panel has not yet been meshed.

The "Subdivide members" option controls whether the members you have drawn to define the meshed panel and its sub-panels, openings and internal walls are subdivided or not. If the members are intended to be a permanent part of the structural model then you would probably want them to be subdivided for proper connectivity with the generated plate elements, however if they are just acting as temporary "construction lines" then there would be no need to subdivide them.

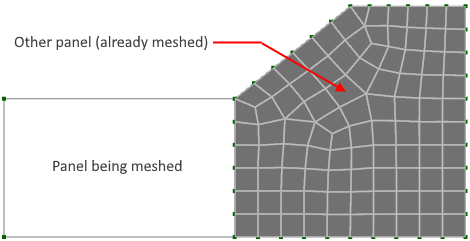

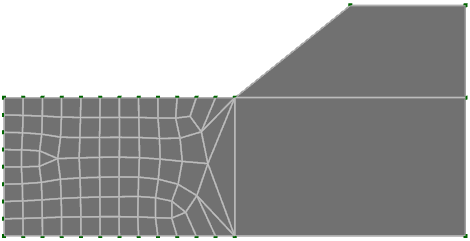

As an example of how to set the "Preserve existing plate edges" option, consider the panel on the left below that is about to be meshed.

If the "Preserve existing plate edges" option is unticked then the following could occur. You can see that along the common edge there are some locations where a node exists partway along the side of an element. These nodes are not connected to the "Other" panel because elements only connect to other elements via their nodes and not along their edges.

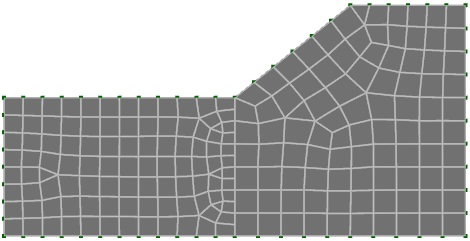

If the "Preserve existing plate edges" option is ticked then you get a much better result with all the elements along the common edge properly connected as shown below.

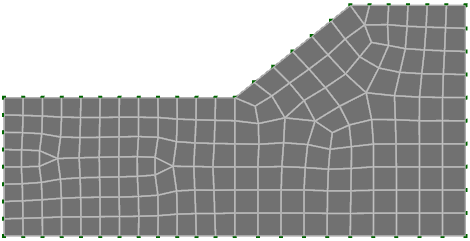

However if the "Other" panel has not yet been meshed then you should untick the "Preserve..." option in order to avoid the following.

The numbering of nodes and plates being generated can be controlled to some extent via the "Start node" and "Start plate" settings. If you leave them blank then the next available numbers will be used.

Finally, don't forget to delete your temporary "construction line" members if they are not part of the structural model. If you leave them in then they will take load and affect the analysis results!

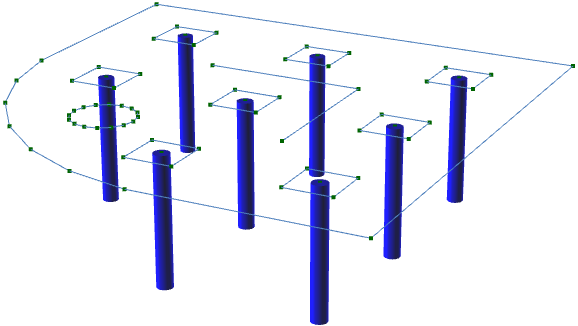

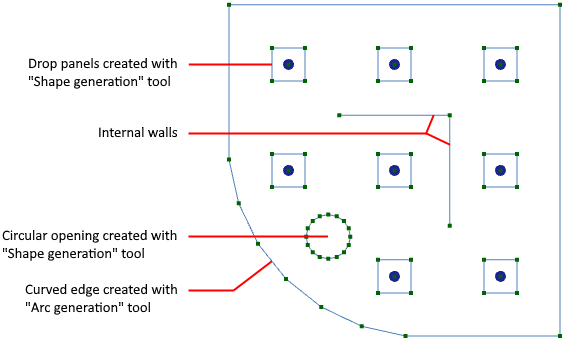

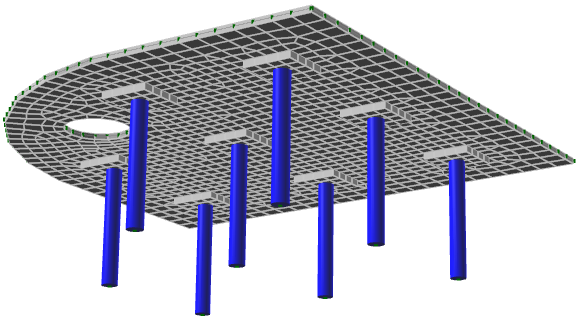

In the following example, a slab supported on columns with drop panels and a circular opening is to be created and meshed. It has been initially defined with members as shown below. Note that all of the normal drawing, alignment and attachment tools can be used when drawing the members. In this particular example, you could also make use of the arc generation tool to create the curved segment of the boundary and the shape generation tools to define the drop panels and the circular opening.

The nodes at the top of each column are treated as "hard nodes" so that they are included in the mesh. All of the lines in the plane of the slab are treated as "hard lines" and in this case they have been used to define the slab boundary, drop panels and circular opening. Two extra open-ended hard lines have been used to define internal walls that will connect to the slab. "Hard nodes" and "hard lines" are simply nodes and lines that you want incorporated into the plate mesh so that you can connect other members or plate elements to them in their defined positions. You may also want to locate hard nodes at other positions of interest such as where specific analysis results are required.

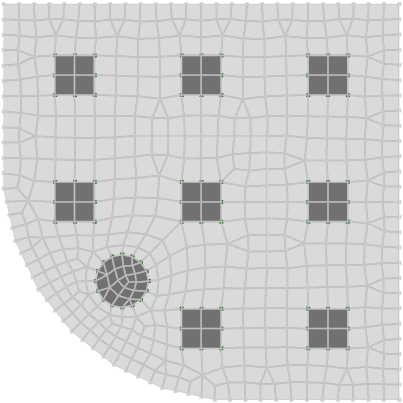

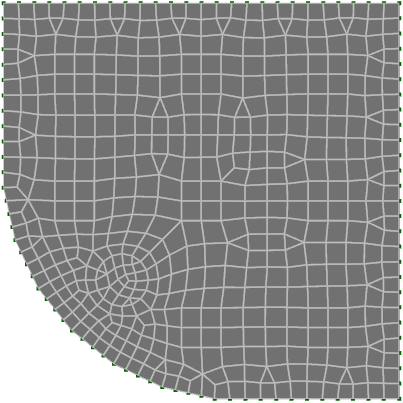

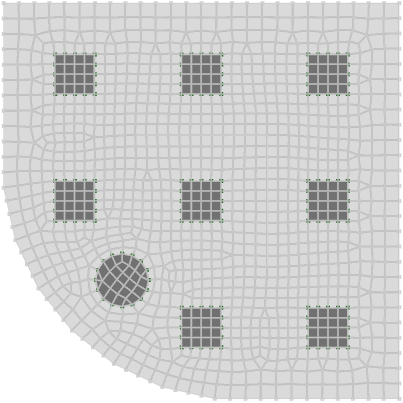

After selecting all the members in the plane of the slab (ie. excluding the columns) and then using a fairly coarse uniform mesh size of 0.6m, the slab is meshed as shown below.

If you look closely you can see that the column nodes, drop panels, circular opening and internal walls are all defined and maintained in their original positions.

In order to refine the mesh around the drop panels we could click the Undo button (or press Ctrl+Z), re-select the members (or press Ctrl+R), right-click and then select "Mesh Tools" => "Generate Plate Mesh from Members" tool again, and then set the "Hard lines" mesh setting to a slightly smaller size as follows.

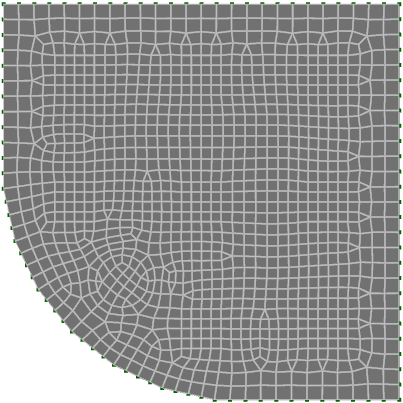

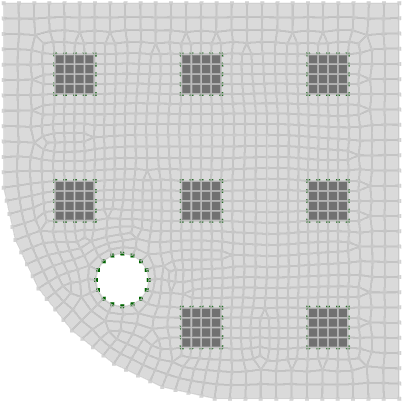

A more refined mesh is then obtained as shown below.

Filters are also created as part of the meshing process, and by selecting the "Sub panels" filter they become more obvious as you can see here.

It then becomes a simple matter of selecting the elements in the circular panel and deleting them to create the opening.

The drop panels can also be selected and their thickness and offsets changed so that they stay level with the top of the slab.

The final step is to delete the temporary "construction line" members that were used to define the slab outline, drop panels, circular opening and internal walls, resulting in the finished product below.

For further information about other plate mesh tools refer to "Mesh tools".